Data Acquisition and Control (DAC)

Function

Table of Contents

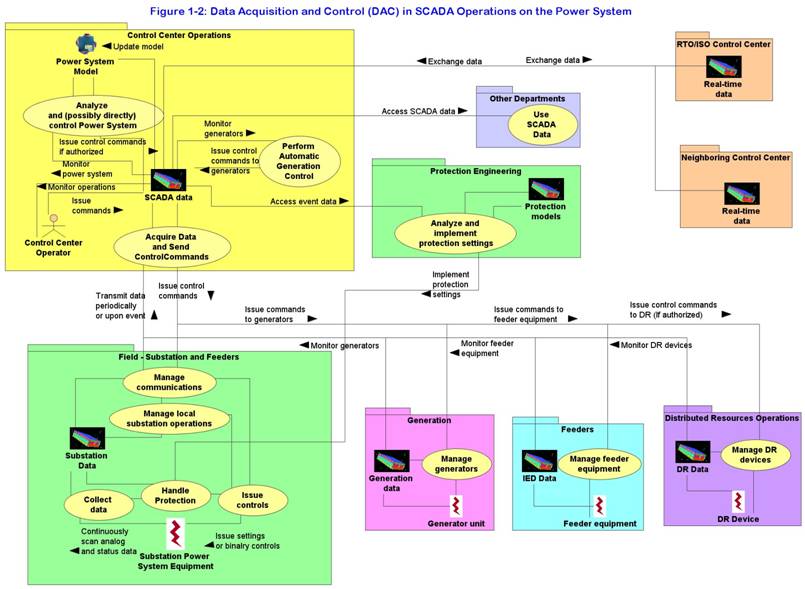

Overview

Scope: The Data Acquisition and

Control (DAC) function, used in transmission and distribution

operations, comprises multiple types of mechanisms for data

retrieval from field equipment and the issuing of control commands

to power system equipment in the field, including among field

devices, between field devices and systems located in substations,

and between field devices and various systems (including, but not

limited to, SCADA systems) located in DER and utility control

centers and engineering/planning centers.

Objectives: The DAC function provides

real-time data, statistical data, and other calculated and

informational data from the power system to systems and applications

that use the data. The DAC function also supports the issuing of

control commands to power system equipment and the setting of

parameters in IEDs and other field systems.

Rationale: Power system real-time data

is source of most information required for power system operations.

Control over the power system equipment can be achieved by issuing

control commands and setting parameters.

The Data Acquisition and Control (DAC)

function, used in transmission and distribution operations,

comprises multiple types of mechanisms for data retrieval and

issuing of control commands to power system equipment. These

mechanisms are often used in conjunction with each other to

provide the full range of DAC interactions. The DAC function, in

turn, is used by other functions, such as Supervisory Control and

Data Acquisition (SCADA) systems, Energy Management Systems (EMS),

Protection Engineering systems, and Advanced Distribution

Automation (ADA), as the means for their interactions with the

power system equipment.

Narrative

Direct power equipment monitoring and control is

performed by an Intelligent Electronic Device (IED), a Remote Terminal

Unit (RTU), or other microprocessor-based controller, sometimes based

on internally generated control commands and sometimes based on

externally requested control commands. These controllers monitor

sensors for data about the power system and their associated power

equipment (the actual equipment connected to the power system). The

communications links are often very short (a few meters) but can also

entail multi-mile links. The communications media typically are copper

wires or optical fibers, but can include power line carrier,

radio-based media, and possibly other media. They either use internal

applications or are instructed by other entities to issue control

signals to associated power system equipment. For example:

·

A Load Tap Changer IED raises and lowers the transformer

tap position according to pre-set algorithms, based on voltage levels

sensed by Potential Transformers (PTs).

·

A circuit breaker IED issues an electro-mechanical or

solid-state-based trip signal to a circuit breaker.

·

A DER IED controller senses status and measurements of a

DER generator and its prime mover, and then issues start and stop

signals.

Diagram

Steps for Direct Power Equipment Control by IEDs

An IED receives

sensor data from a Potential Transformer (PT), or a circuit breaker

IED issues a trip signal to a circuit breaker device.

|

# |

Event |

Name of Process/Activity

|

Description of

Process/Activity |

Information Producer

|

Information

Receiver |

Type of Info Exchanged

|

IntelliGrid Architecture Environment |

|

1.1 |

Continuous or very frequent data retrieval |

Monitor sensors |

IED

performs analog-to-digital and/or

digital-to-digital conversions from

sensor inputs, retrieving data from its

associated power system equipment and

from PT and CT sensors.

IED then

performs basic engineering conversions

on the raw data, processes the

information, and determines if any

subsequent actions are needed based on

limit checking and other process results |

Sensors |

IED |

Raw

sensor data |

Deterministic Rapid

Response intra-substation

environment |

|

1.2 |

Processed data indicates further local action needed |

Send control commands |

IED

issues control commands to power system

equipment, based on the results of

processing the input data from the field |

IED |

Other

IEDs or power system equipment, such as

circuit breakers, voltage regulators,

capacitor bank switches, LTCs,

reclosers, etc |

Signal

data |

Deterministic Rapid

Response intra-substation

environment |

Narrative

Local interactions among Intelligent

Electronic Devices (IEDs) are undertaken to respond to a

relatively local situation. The communications media are typically

LANs, point-to-point cables, and point-to-multi-point radio channels.

Protection actions require very Deterministic Rapid Response communication channels,

with response timeframes of 1 to 4 milliseconds. For example:

·

A protection IED issues a trip command over a

Deterministic Rapid Response

LAN to a circuit breaker IED within a substation, based on its

detection of different power system measurements, such as low

frequency, current overload, etc.

·

Multiple automated switch IEDs, using

point-to-multi-point spread spectrum radio communications media,

respond to a fault condition on a feeder segment by opening and

closing switches to isolate the fault and restore power to unaffected

feeder segments.

Diagram

Steps for Local Interactions Among IEDs

A protection IED issues a trip command over a

Deterministic Rapid Response LAN to a circuit breaker IED within a substation, based on

its detection of different power system measurements, such as low

frequency, current overload, etc.

|

# |

Event |

Name of Process/Activity

|

Description of

Process/Activity |

Information Producer

|

Information

Receiver |

Type of Info Exchanged

|

IntelliGrid Architecture Environment |

|

2.1 |

Continuous monitoring |

Sensor monitoring |

Each IED in the group monitors local power system equipment |

Power system equipment |

IEDs |

Sensor data |

Deterministic Rapid

Response intra-substation

environment |

|

2.2 |

Fault in a feeder segment occurs |

Fault detection |

A fault occurs in a feeder segment. This fault is detected

by one or more IEDs, including a

protection IED in the substation.

|

Sensor or IED |

IED |

Fault sensor data |

Deterministic Rapid

Response intra-substation

environment |

|

2.3 |

Protection IED issues trip command |

Trip command |

The protection IED issues a trip command to the recloser

IED. Using the mechanisms described in

section 2.2.1, the recloser IED issues a

trip command to its recloser. |

Protection IED |

Equipment |

Trip command |

Deterministic Rapid

Response intra-substation

environment |

|

2.4 |

Recloser trips |

Monitor response to command |

The recloser trips and this information is received by

automated switch IEDs on the affected

feeder. |

Sensor or IED |

IED |

Control response sensor data |

Deterministic Rapid

Response intra-substation

environment |

|

2.5 |

IED internal analysis results – multiple iterations |

Local IED response to fault |

IEDs near faulted feeder segment communicate and determine

which switches should be opened and

which closed. This occurs a number of

times, depending upon the results of the

IED actions, the results of the recloser

actions, and the parameter settings in

the IEDs. Each IED performs its actions

via the 2.2.1 process. |

One IED |

Other IEDs |

Digital electric data |

Critical

intra-substation environment |

Narrative

Computerized field systems perform

monitoring and control of field equipment via IEDs, such as a data

concentrator or substation master or Automated Control and Data

Acquisition (ACADA) (SCADA in a control center is considered in

Section 1.4.5). These are generalized systems, as opposed to IEDs or

controllers, and usually monitor and/or control more than one power

system device. Data concentrators just pass data through them, acting

primarily as communication nodes, although they may include a local

database. Substation masters may include applications to perform some

local interactions, or may help coordinate IED actions. ACADA systems

may perform closed loop control (e.g. does not interact with the human

operator before issuing a control command). The communications media

can be LANs, copper wire, optical cables, microwave, radio, leased

telephone lines, cellphones, and many other types. Data exchanges

range from a few 10’s of milliseconds up to 1 second. Examples

include:

·

Data concentrator in a substation monitors data from

IEDs that are located on feeders connected to the substation. It

passes some of this data to a SCADA system and passes control commands

from the SCADA to the IEDs. It may collect sequence of events data and

some statistical information in a database.

·

Substation master coordinates the protection settings of

substation IEDs based on requests from the SCADA system for different

response patterns. For instance, different protection trigger levels

are set for recloser responses if a storm is pending, or if

reconfiguration of a feeder impacts the expected fault current level,

or if DER generation levels could cause fuses to blow unnecessarily.

·

Substation master provides information to automated

switch IEDs on a feeder as to the actual configuration of a

neighboring feeder. This information will permit the automated switch

IEDs to take more appropriate action if a fault occurs.

·

Automatic Control and Data Acquisition (ACADA) performs

Advanced Distribution Automation, by responding to field conditions

reported by IEDs and issuing control commands for volt/var

optimization, fault location, isolation, and restoration, multi-feeder

reconfiguration, and other ADA functions.

Diagram

Steps for Computerized Field Systems Monitoring and Controlling

via IEDs

Substation master coordinates the protection

settings of substation IEDs based on requests from the SCADA system

for different response patterns. For instance, different protection

trigger levels are set for recloser responses if a storm is pending,

or if reconfiguration of a feeder impacts the expected fault current

level, or if DER generation levels could cause fuses to blow

unnecessarily.

|

# |

Event |

Name of Process/Activity

|

Description of

Process/Activity |

Information Producer

|

Information

Receiver |

Type of Info Exchanged

|

IntelliGrid Architecture Environment |

|

3.1 |

On-going monitoring of data by substation master |

Data monitoring |

Substation master receives digital data from IEDs within a

substation and along adjacent feeders.

This data can be transmitted

periodically or upon significant change

of an analog value or upon status change |

Multiple IEDs |

Substation master |

Digital electric data |

Critical intra-substation

environment |

|

3.2 |

Request by SCADA to change protection settings |

Change settings |

As requested by the control center SCADA system, the

substation master determines the

appropriate settings for protective

relays and reclosers for a specific

scenario (e.g. storm, changed feeder

configuration) |

Substation master |

Protection and recloser IEDs

|

Settings |

Critical Operations

DAC |

|

3.3 |

Power system event with IEDs responding |

Sequence of events recording |

A power system event occurs, to which the local IEDs

respond. They then report their sequence

of events to the substation master for

inclusion with disturbance records. |

IEDs |

Substation master |

IED SOE |

Critical Operations

DAC |

|

3.4 |

Operator initiates trip of breaker |

Select before operate (SBO) command |

The substation master ensures that a control request from

the control center is authorized, then

passes the request to the circuit

breaker IED for execution |

Substation master |

Circuit breaker IED |

SBO control request |

Critical Operations

DAC |

Narrative

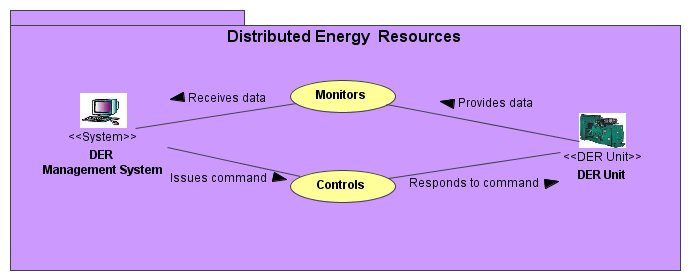

DER management systems perform

monitoring and control of a DER device, either at a customer site or

within a substation or from a utility's distribution control center (see

Figure 1‑1). The DER

management system could be a DER owner’s SCADA system, a customer’s

Building Automation System (BAS), an energy aggregator’s system, or a

distribution operations SCADA system. Communications media can include virtually any type, so long

as response times of a few seconds can be accommodated. Examples

include:

·

Loss of power is detected at a customer site. The backup

diesel generator starts up, the automatic transfer switch connecting

the customer to the utility EPS opens, and the generator is connected

to the customer’s local EPS (or just the critical equipment).

·

The owner of the DER device decides to reduce his load

on the utility EPS by increasing generation. The DER operator

implements this decision by setting new parameters in the DER

management system. (These are manual actions by

persons.) As an automated result, another generator is started by

the DER management system, synchronized with the local EPS, and

interconnected.

·

An energy aggregator sets groups of DER devices to cycle

on and off over the next day, taking into account pollution limits,

the real-time price of energy, and contractual arrangements with the

owners of the DER devices.

·

While a DER device is interconnected with the utility

EPS, a fault occurs on the feeder. The DER management system ensures

that the DER device either trips off or the interconnection circuit

breaker opens.

·

The DER management system collects sequence-of-events,

performance data, and statistical information from DER devices in a

substation.

Diagram

Figure DER Management Systems Monitoring and Control of DER

Devices

Steps for DER Management System Monitoring and Control of DER

Devices

The owner of the DER device decides to reduce

his load on the utility EPS by increasing generation. The DER operator

implements this decision by setting new parameters in the DER

management system. (These are manual actions by persons.) As an

automated result, another generator is started by the DER management

system, synchronized with the local EPS, and interconnected.

|

# |

Event |

Name of Process/Activity

|

Description of

Process/Activity |

Information Producer

|

Information

Receiver |

Type of Info Exchanged

|

IntelliGrid Architecture Environment |

|

4.1 |

DER owner decides to reduce load |

Owner decision |

DER owner contacts (calls, e-mails, alarms) DER Operator

that additional energy from DER

generation is needed. |

DER owner |

DER Operator |

Call by person |

Call – Outside Scope of IECSA |

|

4.2 |

DER operator enters new parameters |

Establish parameters |

DER Operator sets new parameters for DER generation output

in the DER management system. |

DER Operator |

DER Management system |

DER data entry |

User interface (Outside scope of IntelliGrid Architecture) |

|

4.3 |

Start command |

Start DER |

DER management system issues start command to a DER unit. |

DER management system |

DER unit |

DER start-up command |

DER Monitoring and Control |

|

4.4 |

DER Unit started |

Synchronization |

DER Unit starts and synchronizes with the Local EPS, and

reports success and current operating

measurements to DER management system |

DER unit |

DER management system |

DER reporting |

DER

Monitoring and Control |

|

4.5 |

On-going DER unit operations |

Monitoring DER |

DER unit reports current operating measurements to DER

management system for operational

information as well as historical and

statistical information |

DER unit |

DER management system |

DER historical and statistical records |

DER

Monitoring and Control |

|

4.6 |

Environmental limit reached

|

Environmental limit |

DER management system calculates that a diesel generator has

reached its daily (assigned) limit of

emissions, and issues a stop command |

DER management system |

DER unit |

DER stop command |

DER

Monitoring and Control |

|

4.7 |

DER unit stops |

Stop DER |

DER unit stops and shuts down. It reports back to the DER

management system with its latest data |

DER unit |

DER management system |

DER reporting |

DER

Monitoring and Control |

|

4.8 |

DER unit reports received |

DER reports |

DER management system provides DER unit data to DER operator

via a User Interface |

DER management system |

DER operator |

User display |

User

interface (Outside scope of IntelliGrid Architecture) |

Narrative

SCADA systems perform remote monitoring

and control of field equipment and IEDs (see Error! Reference source not found.).

The term “SCADA” is used here to imply any centralized system which

retrieves data from remote sites and may issue control commands when

authorized. These SCADA systems are typically located in a utility

control center, but may include an engineering “SCADA” system which

retrieves protection data or disturbance data, or a maintenance

“SCADA” system which monitors the health of both power system and

communications equipment.

SCADA system monitoring can use communication

channels directly to IEDs, via Remote Terminal Units (RTUs), through a

data concentrator, through a substation master, or through a DER

management system. The communications media can include virtually any

type, so long as response times of 1 second can be accommodated.

Although typically seen as used only for real-time distribution

operations, the data acquired by the SCADA system can be used by many

different systems, applications, and personnel in the control center.

This Use Case is limited to the monitoring and control function by

SCADA systems; other Use Cases (e.g. ADA Use Case) describe their

interactions with the SCADA systems.

SCADA system monitoring and control examples

include:

·

Power system operations SCADA system receives real-time

data from power system equipment via:

– RTUs

– IEDs

inside substations

– IEDs

along feeders

–

Substation masters

– DER

(or other generation) management systems

– Other

control centers

–

Manual entry

·

Power system operations SCADA system issues control

commands to power system equipment in real-time via:

– RTUs

– IEDs

inside substations

– IEDs

along feeders

–

Substation masters

– DER

(or other generation) management systems

– Other

control centers (if authorized)

·

Power system operations SCADA system receives metering

information

·

Data management “SCADA” system receives power equipment

configuration data from devices. It may have its own communication

channels to the remote sites, or it may acquire this data through the

distribution operations SCADA system

·

Engineering “SCADA” system receives sequence of events

data, oscillographic data (special handling required), historical

data, and statistical data. It may have its own communication channels

to the remote sites, or it may acquire this data through the

distribution operations SCADA system

·

Maintenance “SCADA” system receives data related to the

health of power system equipment and communications equipment. It may

have its own communication channels to the remote sites, or it may

acquire this data through the distribution operations SCADA system.

·

Planning “SCADA” system receives data that can be used

for statistical analysis of power system measurements: maximums,

minimums, averages, trends, profiles, power quality metrics, etc,

needed for short and long term planning.

Diagram

Steps for Monitoring and Control by SCADA System

Distribution operations SCADA system monitors

and controls power system equipment via a multitude of mechanisms.

|

# |

Event |

Name of Process/Activity

|

Description of

Process/Activity |

Information Producer

|

Information

Receiver |

Type of Info Exchanged

|

IntelliGrid Architecture Environment |

|

5.1 |

Establish an association between SCADA and RTU and/or IED |

Establish association |

Using an interactive process between an RTU or IED and a

SCADA system, an association is

established. This interactive process

varies from protocol to protocol, but

essentially entails setting up what data

is available and what data is to be sent

under what conditions. In some

protocols, many of the steps are manual,

while in others they are almost entirely

automatic. |

SCADA and RTU/IED |

RTU/IED and SCADA |

Association |

Critical Operations

DAC |

|

5.2 |

Status change occurs in power equipment |

Detect status change |

A status change occurs in some power system equipment. This

status change is “immediately” sent

(usually within 1 second) to the SCADA

system. Depending upon the

communication “services”, the status

value can be sent periodically, or can

use the “report-by-exception” service,

which sends a status value only if it

changes |

IED which is sensing power system equipment |

SCADA system |

Status change |

Critical Operations

DAC |

|

5.3 |

“Significant” change in a measurement value |

Detect significant measurement change |

A significant change occurs in a measured value. (Significant

implies it exceeds some pre-established

limit.) This changed value is sent

according to pre-established protocol

services: e.g. report-by-exception

sends it immediately (within 1 to 2

seconds), while periodically

sends it when the time period elapses.

The protocol also determines what information is included,

such as timestamp, quality code, etc. |

RTU which is sensing power system equipment

|

SCADA system |

Measurement change |

Critical Operations

DAC |

|

5.4 |

SCADA issues control command |

Issue control command |

Either an operator or an application issues a control command

through the SCADA system to an RTU or

IED. These control commands are

typically immediately implemented by

sending a signal to the power system

equipment |

SCADA |

RTU or IED which initiates signals to power system equipment |

Control command |

Critical Operations

DAC |

|

5.5 |

SCADA sends parameter settings |

Set parameters |

Either an operator or an application sends a parameter

setting through the SCADA system to an

RTU or IED. These parameter settings may

be stored for later use or may be used

immediately to initiate a signal to the

power system equipment, such as a raise

or lower control command |

SCADA |

RTU or IED |

Parameter setting |

Critical Operations

DAC |

|

5.6 |

SCADA requests specific data |

Request data |

Either an operator or an application requests specific data

to be sent to the SCADA system from an

RTU or IED. |

SCADA |

RTU or IED |

Request |

Critical Operations

DAC |

|

5.7 |

Sequence of Events log |

Transmit sequence of events records |

An RTU or IED has collected Sequence of Events log and

initiates its transmittal to the SCADA

system |

RTU or IED |

SCADA |

SCADA SOE |

Critical Operations

DAC |